Hochschularbeit

| Karin von Lerber: | laser cleaning of undyed silk - a study | Zurück |

| Sprache: | Original - Übersetzung | |

| Seitenübersicht: | ||

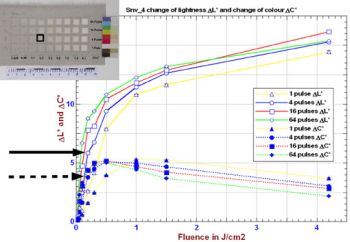

Carbon soiled silk after the laser cleaning tests. The effect is visible on the reverse as well as on the obverse.

|

|

Colorimetry. Difference in lightness (delta L*) versus colour (delta C*). Ideally, dirt should be removed (increase dL*) without coloration. Not the case.

|

|

| Zusammenfassung: | The influence of laser irradiation on undyed, unweighted silk was tested. A computer controlled Qswitched Nd:YAG laser at 532 nm was used to tread three different sample fabrics: a new, clean silk, a new silk, artificially soiled with carbon dust, and naturally aged silk of unknown provenance. 12 different combinations of fluence and pulse numbers were tested: 0.5, 1.0, 1.5 and 4.2 J/cm2 with 4, 16 and 64 pulses. An additional set of the artificially soiled silk for 0.025, 0.05, 0.1, 0.2 and 0.3 J/cm2, was included. The resulting laser cleaned samples were evaluated visually and with analytical techniques. The visual observations were made with and without microscopy under vis and uv-light. Analytical techniques included colorimetry, focused ion beam scanning electron microscopy (FIB-SIMS), viscometry, and Fourier transform spectroscopy (FTIR) with and without polariser. The following factors were observed for changes: morphological appearance of the fibre surface, light absorption, ease of ionizing the surface, degree of polymerization, and over all crystallinity and orientational order of the crystallites within the fibre. While changes in the physical integrity of the fibre surface occurred at fluence and pulse numbers (way) over the tested parameters, chemical changes within the fibres could be detected as low as 0.2 J/cm2 at 4 pulses. This being the minimal fluence at which carbon dust can be removed successfully. Occurring changes are visible as yellowing at low, and as bleaching at higher fluence and pulse number combinations. At least two different chemical reactions occur at the same time. At low fluence and pulse numbers, processes leading to polarized groups are prominent, whereas at higher fluence and/or pulse numbers, they are outweighed by processes leading to conjugated systems. As at least two processes are occurring concurrently, the development of polar groups can not automatically be linked with chain scission, nor the conjugated systems with crosslinking. The three tested silk fabrics underwent different changes in different degrees upon laser irradiation. This supports the assumption, that the degree of deterioration and soiling significantly influence the interaction between laser and silk. The results of this study suggest, that laser cleaning, even at low fluence and pulse number, poses the chemical integrity of undyed and unweighted silk fabrics at significant risk. This risk might even be higher when using hand held laser tools. |

| Schlagworte: | silk, laser Nd-YAG |

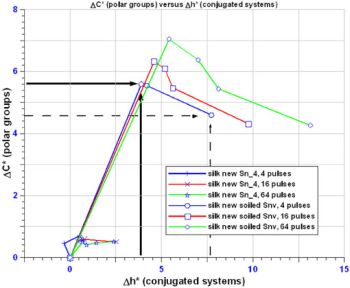

Colorimetry: at the same time, polar groups and conjugated systems are created. With higher fluece, the latter dominate.

|

|

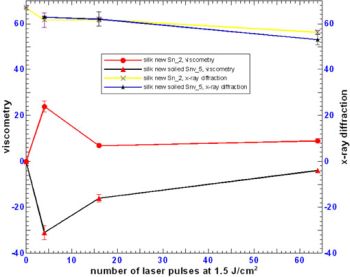

Viscometry = compilation of chain scissions and new conjugated System. X-ray diffraction shows decrease of overall crystallinity with increasing fluence.

|

|

| weitere Angaben: |

|

| Kontakt: |

Karin von Lerber Oberseenerstr. 93 Prevart GmbH - Atelier für Textilkonservierung CH-8405 Winterthur Schweiz - Switzerland karin.vonlerber@[Diesen Teil loeschen]prevart.ch www.prevart.ch |

| Download: |

Volltext der Hochschularbeit (pdf-Format, ca. 8.82 MB) |

| DOI (Digital Object Identifier) | 10.5165/hawk-hhg/110 |

Das Hornemann Institut verfügt ausschließlich über die hier angezeigten Informationen. Für weitere Informationen oder Kopien der Hochschularbeit wenden Sie sich bitte an den Autor/die Autorin - oder wenn kein Kontakt angegeben ist - an die Sekretariate der jeweiligen Fakultäten.